PRODUCTS Flow Meters

K-600 series GLASS ROTORMETER for ULTRA-PURE APPLICATIONS

Operational function:

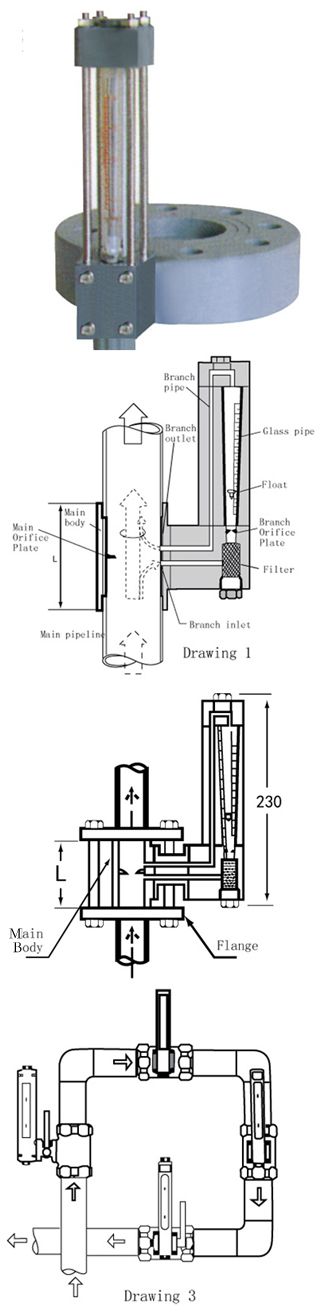

Illustrated as drawing 1, when the liquid pass through main hole's plate, the pressure difference between front side and back side happens, there is a respondent function relation between the pressure difference and flow speed. Installing a small rotor flow meter on the in-outlet of branch, i.e. to make that the flow volume through small rotor flow meter is same to the volume through main pipe, therefore the flow volume's data in main pipe can be read through buoy position and scale on small rotor flow meter. The cut-off valve installed between measure pipe and indicator can make the flow meter's take-down or repair conveniently when the main pipe is being in normal working situation.

Specification

D N (mm) | Measure Range | ||

Water(m3/h) | Air(Nm3/h) | ||

10 | 3/8" | 0.08-0.42 | 0.8-4 |

15 | 1/2" | 0.18-0.96 | 2-9.2 |

20 | 3/4" | 0.45-2.4 | 5-23 |

25 | 1" | 0.8-4.2 | 8-40 |

32 | 1-1/4" | 1.2-6.4 | 12-60 |

40 | 1-1/2" | 1.8-9.4 | 18-90 |

50 | 2" | 3.5-18.5 | 35-175 |

65 | 2-1/2" | 6-32 | 60-300 |

80 | 3" | 8-42 | 80-400 |

100 | 4" | 16-80 | 160-800 |

125 | 5" | 25-125 | 250-1250 |

150 | 6" | 35-180 | 350-1700 |

200 | 8" | 60-320 | 600-2800 |

250 | 10" | 90-480 | 900-5000 |

300 | 12" | 160-820 | 1600-7800 |

350 | 14" | 200-1000 | 2000-9500 |

400 | 16" | 300-1500 | 3000-14500 |

450 | 18" | 400-2000 | 4000-19000 |

500 | 20" | 500-2500 | 5000-24000 |

Manual instruction

Up/Down straight pipe

For purpose to measure the flow speed precisely, recommend to

use below straight pipe diameter:

90° Elbow pipe | Opening valve | |

Up straight pipe diameter | 6D | 8D |

Down straight pipe diameter | 3D | 3D |

Flow direction:

The product can be changed different directions illustrated as drawing 3. the flow direction can divide as: bottom-top, left-right, right-left and top-bottom. It is easy to change flow direction on the spot. Attention: special flow volume' specification can be customized according to technical data provided by customers.